BASICS OF ROLL FORMING ALUMINUM

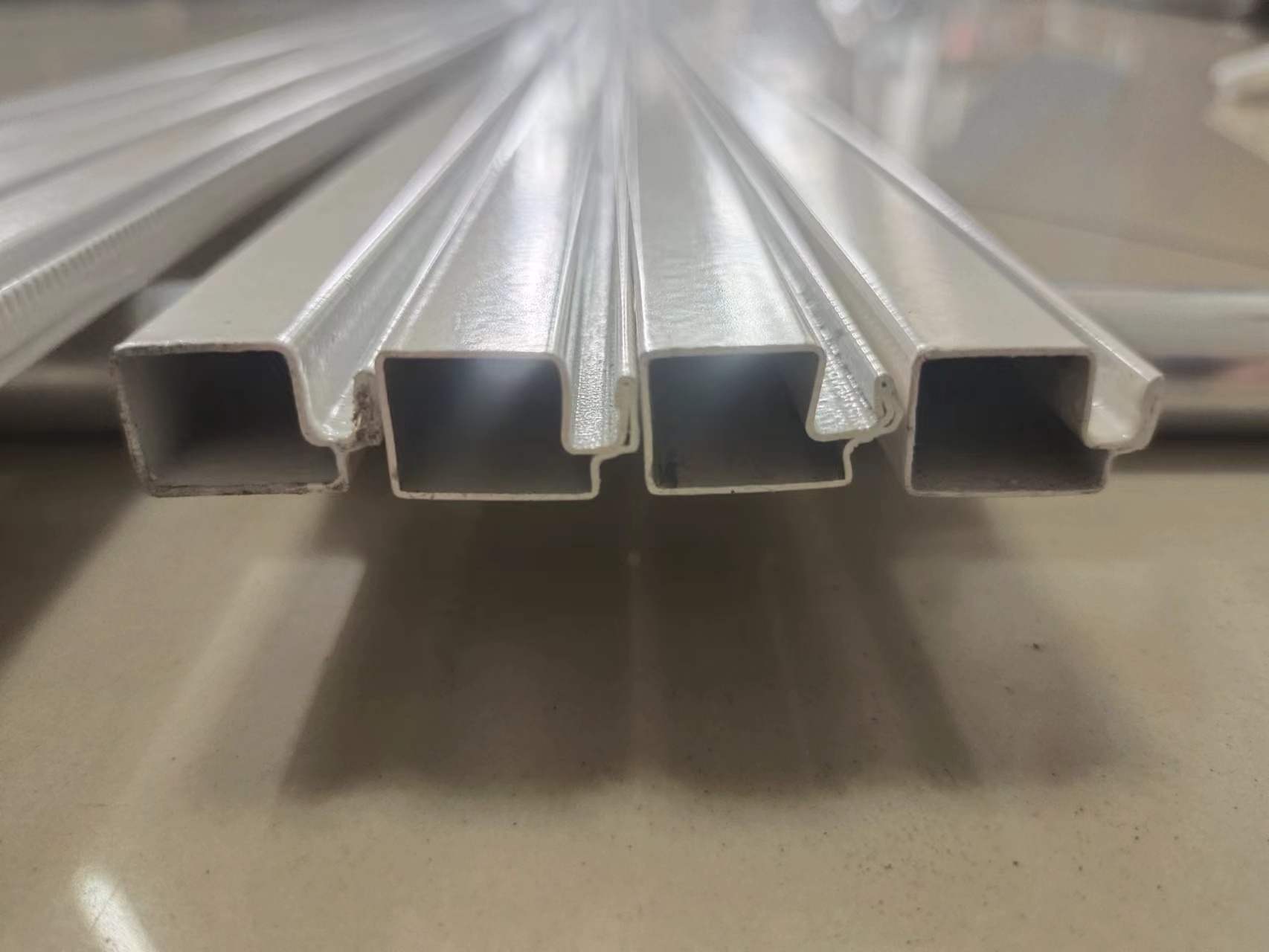

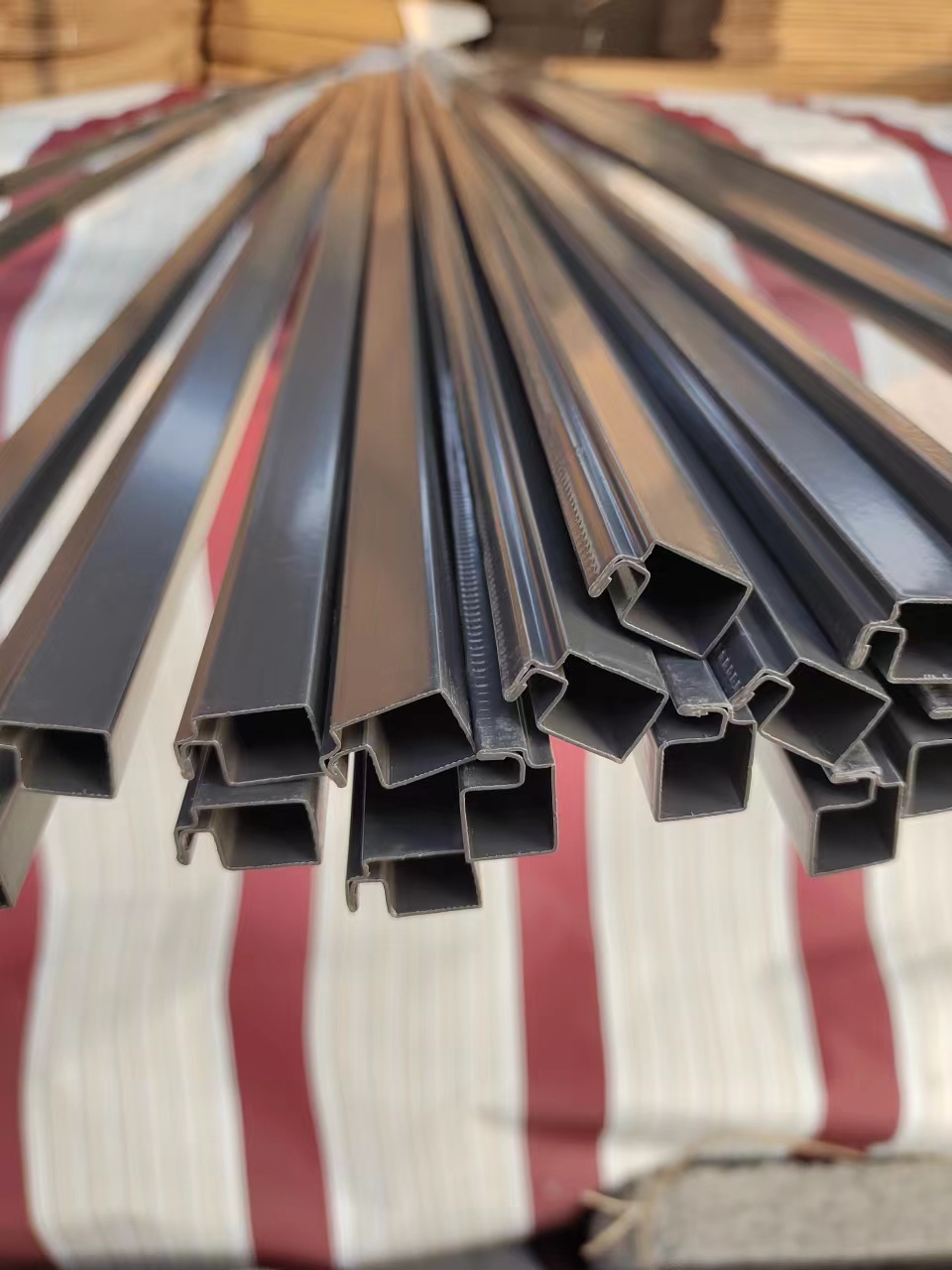

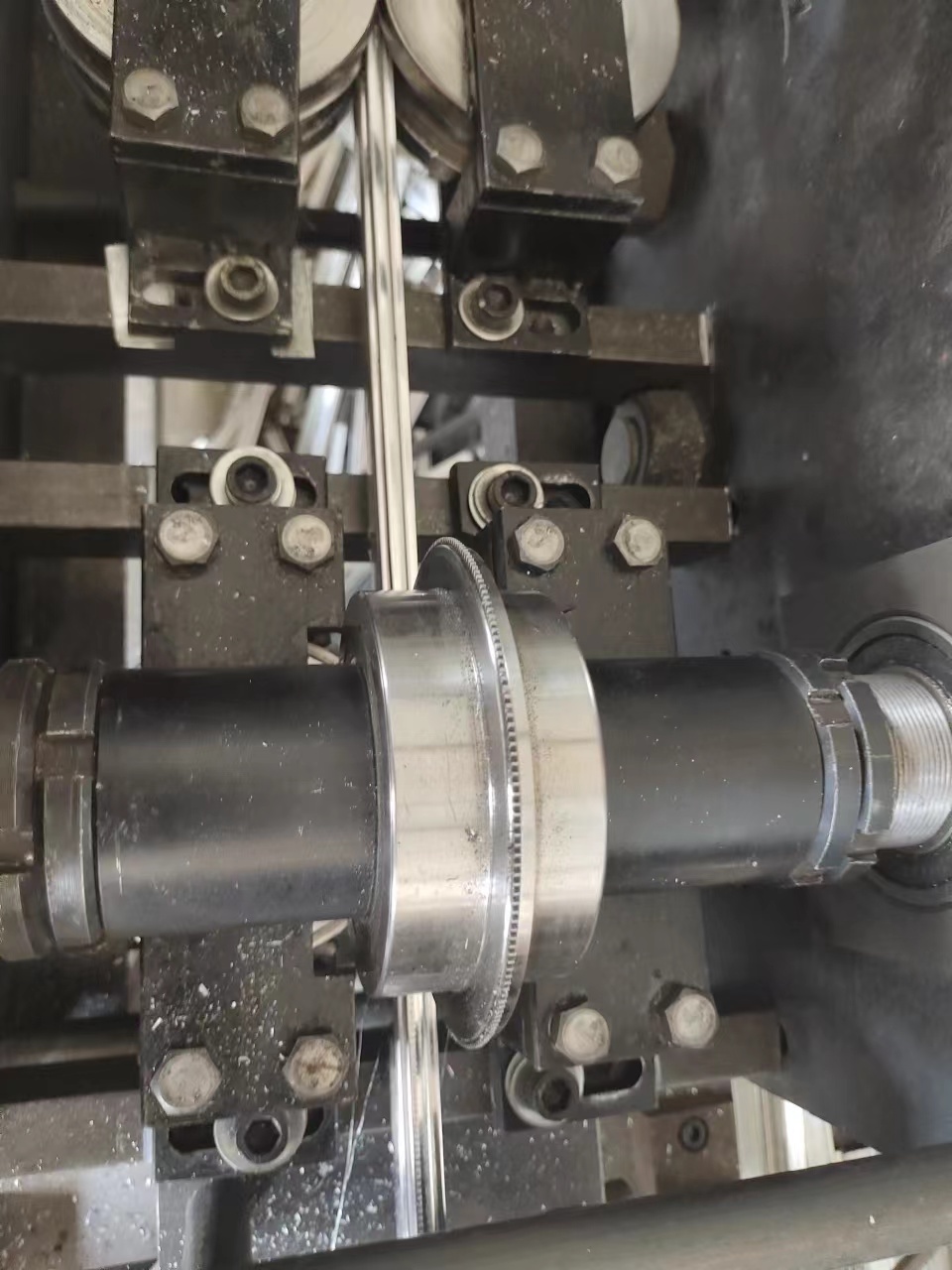

Roll Forming, sometimes called sheet roll forming, is a continuous bending operation where aluminum, typically in the form of sheet metal, is passed through sets of rolls that progressively shape it into a desired cross-sectional profile. This process is especially advantageous for producing long lengths and large quantities of structurally sound parts.

ADVANTAGES OF ROLL FORMING

Consistency: Produces parts with uniform thickness and consistent shapes.

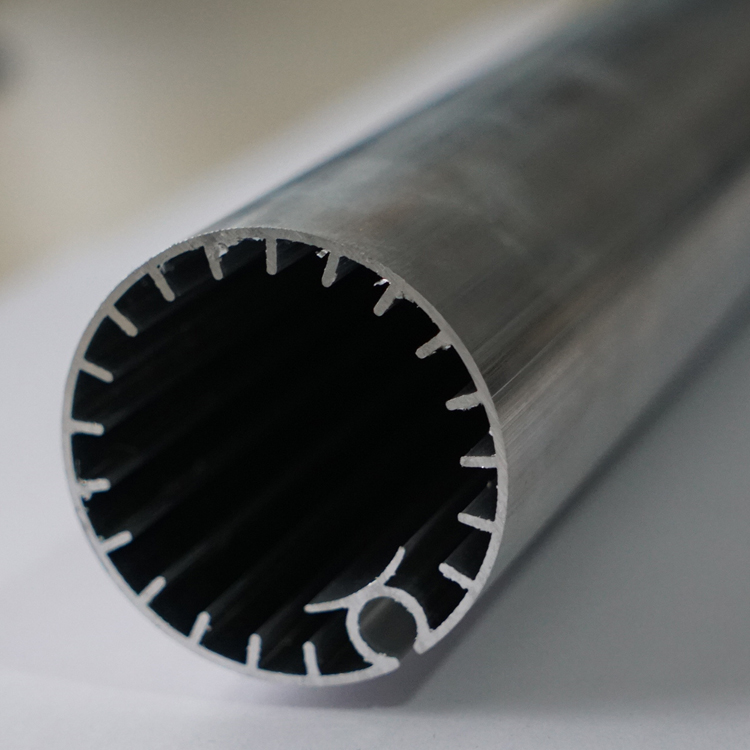

Flexibility: Can produce a wide range of cross-sectional profiles.

Efficiency: Ideal for high-volume production due to its continuous nature.

APPLICATIONS OF ROLL FORMED ALUMINUM

Construction: Roofing, wall panels, and framing.

Transportation: Rails, bumpers, and automotive parts.

Industrial sectors: Racking systems and conveyor belts.