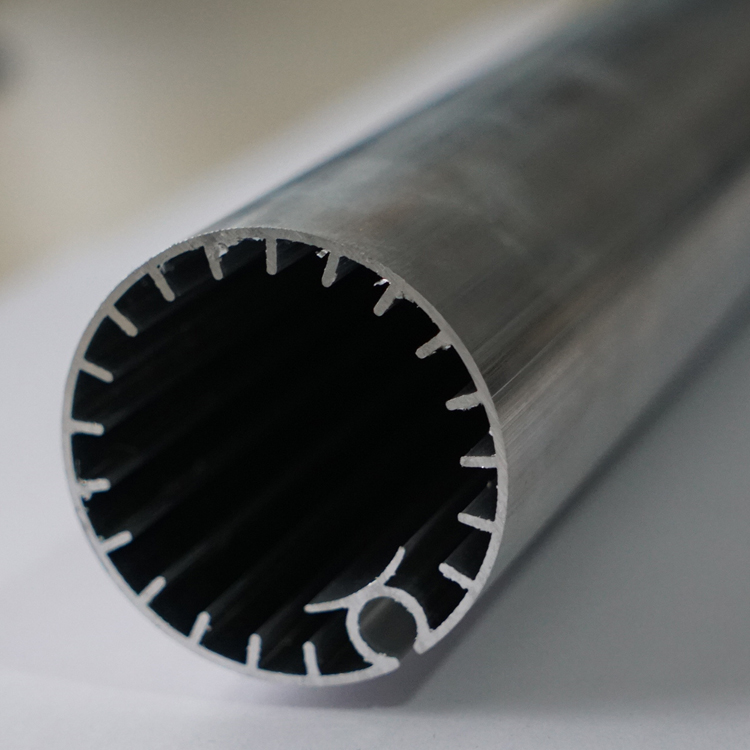

| China High Quality 6063 Aluminum Extrusion Profiles | ||||||

| Alloy&Temper: | 6063 | T4/T5/T6 | ||||

| Certificate: | ISO9001:2008 | PVOC | ||||

| Surface finish: | Mill finish | Anodizing | powder coated | Wood grain | Polished | sand lasting |

| Anodizing: | Silver/champagne/bronze/black. Anodizing thickness of 10um | |||||

| powder coating: | Many different color choices. Powder coating thickness 40um-120um. | |||||

| Wood grain: | Premium quality heat transfer printing paper for different textures of wood grain | |||||

| OEM&ODM service: | Moulds creation as per customers’ drawing, or to scan the cross section as per customer’s delivery samples. | |||||

| Packing Details | 1. Protective Film + Heat Shrink Film 2. Protective Film 3. Kraft paper 4. EPE Foam for Each Piece + Heat Shrink Film |

|||||

-

Heat-resistance fireproof broken bridge aluminu...

-

Photovoltaic Module Aluminum Profile Frame Sola...

-

Window And Door Profiles 6063 Anodized Aluminum...

-

Customized Industrial Extruded Aluminium Profil...

-

Screen window aluminium 6061 t6 tube profiles

-

aluminium profiles China supplier factory indus...